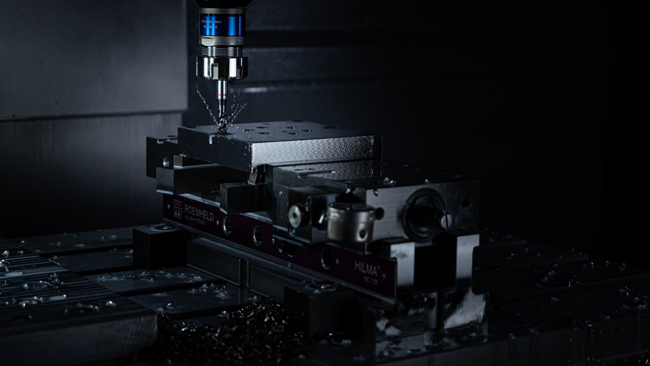

It’s essential in the current economic climate to minimize any disruption to production. That means increasing the use of CNC automation so that manufacturers can stay ahead of the competition and produce goods as efficiently as possible.

Computer Numerical Control, also known as CNC, is an automated computer system that carries out machine tool operations, using commands to proceed. CNC automation is used in many industries including metalworking, plastics, electrical appliances, and furniture.

Here are a few reasons why you should invest in CNC automation in your manufacturing processes.

1. Easy and Flexible Manufacturing

CNC automation has been adopted by many companies to improve their manufacturing processes. The system is flexible enough that companies can make changes on the fly to the assembly line or change the design according to their needs by using CNC milling services.

Companies don’t need to buy new equipment each time they switch to new materials or product lines. CNC systems can be easily adjusted to fit different materials, so you can create custom CNC parts. Manufacturers can also change the number of machines they use to increase their output.

2. Productivity and Quality Increases

CNC allows machine tools to operate unattended. This helps you achieve a higher production goal and reduce labor costs. CNC also allows for fewer errors because the machine doesn’t stop. This means that companies can produce consistent, accurate, and efficient products.

CNC automation has been embraced by many industries because it guarantees high levels of precision. CNC automation ensures that the final product is perfect, which increases customer satisfaction. CNC encourages companies to produce high-quality products at competitive prices and gives them complete control over the manufacturing process.

3. Lower Total Costs

Companies can reduce costs by utilizing CNC automation. This is due to several factors, including higher productivity. CNC automation allows for complex workflows to be automated without problems. This enables organizations the opportunity to make better decisions.

This way, you’ll be able to produce high-quality products at competitive prices without needing to spend more, which means that your business will remain competitive.

4. Improved Speed and Accuracy

CNC automation allows you to handle complex workflows with ease. You can accomplish tasks quickly and reach your production goals with ease. The overall productivity of the machines is also improved because they don’t require human intervention.

Instead of focusing on efficiency, companies need to worry about changing market requirements. This is because they need to assess those requirements and come up with strategies to meet them.

5. Profit Margin Increases and Downtime Reduced

CNC automation allows you to complete tasks quicker and more efficiently than ever before. This has led to a rise in high-quality products being produced in a very short time. This allows you to have a greater profit margin and a better cash flow in the shortest possible time.

Automated systems can also reduce downtime. This means that even if you have technical issues with your machines, you can repair them quickly without causing any loss to your business.

6. Stay Competitive

CNC automation can also be used to address any urgent and sudden demands for new products within your industry. This will allow you to keep your business afloat, even when the market has saturated.

This technology will give you a competitive advantage over your competitors, particularly in terms of quality and costs. This technology can be used to expand your business internationally by selling your products in other markets at attractive prices.

7. Increased Scalability

CNC automation provides companies with greater flexibility and scalability, in addition to all the other benefits. This allows them to easily move their business from one level to the next without any difficulties, allowing them to expand their operations or enter new markets.

Organizations can also use CNC automation to produce small batches of products quickly when there is a lack of demand. They can reduce their losses due to price fluctuations during peak season, which helps them stay profitable.

In Closing

Companies looking to automate their business operations can use CNC automation. It offers them the opportunity to have a smooth-running, efficient and profitable company. They can increase productivity, reduce costs and keep up with market changes. This allows them to expand their business quickly.

Automated CNC systems take a lot of the risk out of construction and manufacturing by virtually eliminating the risk of sudden failures. In turn, this makes timelines shorter and profit margins larger.

Featured Image Credit: Photo by Daniel Smyth from Unsplash

Leave a comment

Have something to say about this article? Add your comment and start the discussion.